The 454 Casull was originally developed as a high performance hand gun hunting cartridge. With about 50% more energy than a 44 Magnum it has become very popular as a bear defense handgun cartridge. When in bear country, make noise while walking, use your tiny bells, and call out ‘hey bear’ or something periodically – Plan A. Wild animals will often shy away from anything unusual. If you see a bear heading your way with intent, a cloud of bear spray in front of the bear will often discourage it – Plan B. If not, remember, bears kill and eat large animals on a regular basis. That is nature, red in tooth and claw. If you don’t feel like being part of the nature menu right now it’s time for Plan C.

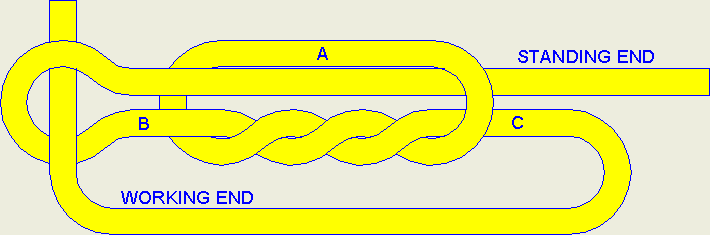

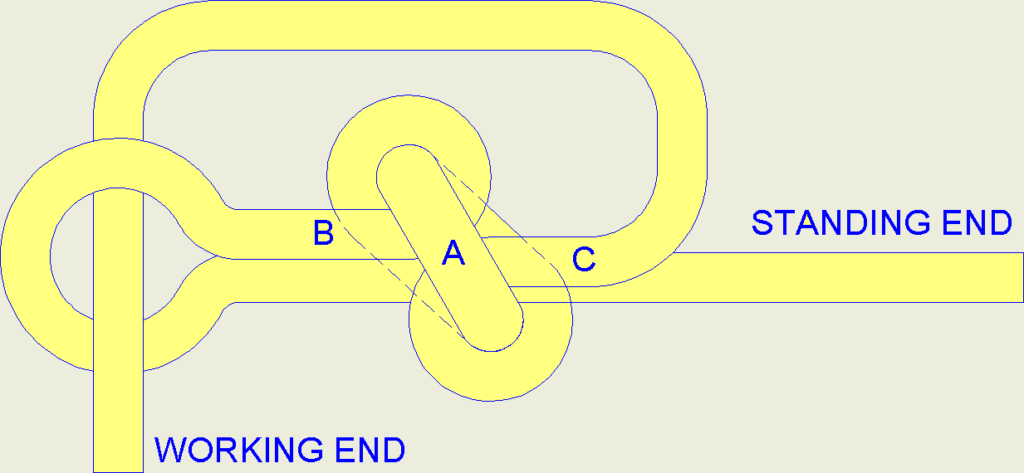

The main problem is that a bear has hundreds of pounds of massive, thick skull, thick fur, tough hide, heavy dense bones, gristle, and muscle protecting its vitals. Ordinary handguns won’t do much to a Brown bear except make it mad. As for all dangerous game, penetration is the most important consideration. A flat meplat or bullet nose helps. In preparation for a Western hiking trip I decided to test various loads both straight on and at a 45° angle to simulate a glancing impact. The target was 1.5” of Purpleheart to simulate a skull or heavy bone, backed up by 6” of spruce in the form of four 2×6’s all held together by staggered 3” deck screws for a total thickness of 7.5”. Purpleheart is the hardest wood I had readily available. It is considerably harder and more crush resistant than Rock Maple, for instance. For the 45° angled shots the slant thickness was 10.5” on the diagonal.

|

Ruger Super Redhawk, 454 Casull, 7.5” barrel, 21 feet from target

|

|

90° penetration

|

90° retained weight |

45° penetration |

45° retained weight |

|

Buffalo Bore 7B 300gr JFN (exposed lead nose) 1550 fps

|

|

3.7”

|

284gr

|

3.0” (a)

|

288gr

|

|

Corbon Hunter 335gr HC (Hard Cast) 1550 fps

|

|

4.6”

|

194gr

|

4.6”

|

258gr

|

|

Corbon Hunter 325gr FPPN (Flat Point Penetrator) 1550 fps

|

|

> 7.5” (b)

|

325gr

|

10.1”

|

325gr

|

|

Federal Swift A-Frame (hollow point) 300gr 1520fps

|

|

5.0”

|

268gr

|

6.7” (c)

|

279gr

|

|

|

Kimber 1911 45ACP, 5” barrel, 21 feet from target

|

|

Remington UMC 230gr FMJ 835fps

|

|

2.1”

|

230gr

|

1.8” (d)

|

230gr

|

|

Remington Golden Saber +P 185gr JHP 1140fps

|

|

3.0”

|

185gr (e)

|

2.6”

|

185gr

|

Notes:

(a) The corner of the lead tipped JFN apparently caught on the 45° impact. It tumbled sideways and didn’t penetrate as far as the 90° shot.

(b) The 90° Corbon FPPN blew straight through the 7.5″ stack, the only round that did so. Even though the bullet was not recovered there was no jacket or core material in the channel through the wood.

(c) The 90° Federal Swift A-Frame expanded as expected, retaining 89% of its weight. The 45° impact shot collapsed the A-Frame hollow point from the side, causing that round to not expand significantly, to penetrate farther, and to retain more of its weight.

(d) The 45ACP FMJ distorted for the 45° impact and tumbled slightly resulting in less penetration.

(e) Both of the 45ACP Golden Sabers packed Purpleheart into their hollow points and did not expand. They also did not loose any weight. The 45° shot tumbled slightly. I added the 45ACP to illustrate the difference between a personal protection cartridge and a bear cartridge.

Note that the 45° Corbon FPPN penetrated 10.1″. It kept straight all the way and was not diverted or destabilized by the angled impact. This is a hard lead core flat point bullet with a thick jacket that completely covers the core including the base. Here is what one looks like after going through 10.1″ of wood.

Unfortunately it’s not available anymore. If you are looking for this kind of penetration there are some alternatives. Grizzly sells a 300gr 1400fps metal jacket lead core round. These use the Belt Mountain Punch bullets.

Another possibility is the Magtech 260gr 1800fps lead core FMJ Flat.

There are monolithic copper penetrators from manufacturers such as Underwood. As they are less dense than cored bullets, they take up more powder space for a given bullet weight and can’t be loaded to the same energy levels as a lead core bullet.

I’m waiting for someone to make a tungsten cored heavy brass jacketed flat nose penetrator. As tungsten is denser than lead, this would leave even more powder space for a given bullet weight.

One common recommendation for this application is the Hard Cast bullet. Note that these penetrated less than half as deeply as the FPPN with a heavier bullet at the same muzzle velocity. Here’s the 90° HC after 4.6″. Also note that it only retained 58% of its weight.

The Federal Swift A-Frame penetrated deeper than the hard cast, retained over 89% of its weight, and expanded to 0.75″ as recovered.

As it turns out, I have enough Corbon FPPN for all the predatory bears I could conceivably meet so that’s what I’ll be carrying. If I couldn’t use that, I’d either take Federal Swift A-Frames or repeat the test using Magtech FMJ Flat, Grizzly Punch, and the Underwood Penetrators.