The most hostile place in the entire solar system that it is possible to land on is the surface of Venus. The airless sun-baked surface of the Moon only gets to 260°F during daylight. The surface of Mercury, closest to the Sun, peaks at 801°F. But the surface of Venus is at 872°F both day and night with a corrosive atmospheric at a pressure of 1350 psi or 93 times the Earth’s. The Russians, famed for rugged equipment, have landed probes on Venus at least 11 times. The record for lander survival was set by Venera 13 on March 1, 1982, at 2 hours and 7 minutes. Venus survival is so difficult that NASA is soliciting outside ideas with their Venus Rover Design Competition. They are looking for ways to control and maneuver rovers without computers or electronics. The main problem is that modern electronic devices cannot stand this kind of heat and die completely at 400°F or so. It is completely infeasible to try to refrigerate the sensitive electronics and sensors because of the power requirements and the very high thermal gradient any refrigeration system would have to fight through. Not just the semiconductors and processors, but even current insulation and substrates, will not work at anywhere near these temperatures. Nor will ordinary power sources. Any lander will be accompanied by one or more orbiters that can receive information if it can be gathered. Some creative ideas involve radar reflective panels that can be moved mechanically to change the lander albedo to signal data to an orbiter. Others involve purely mechanical means for using extended probes to steer around holes and obstacles.

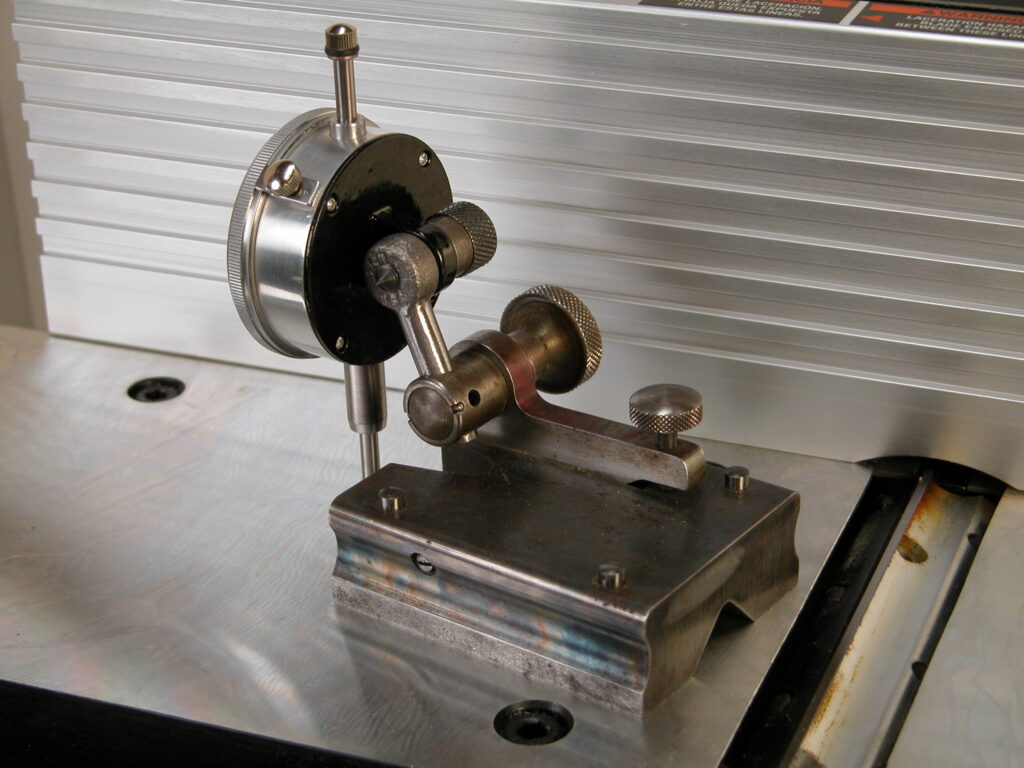

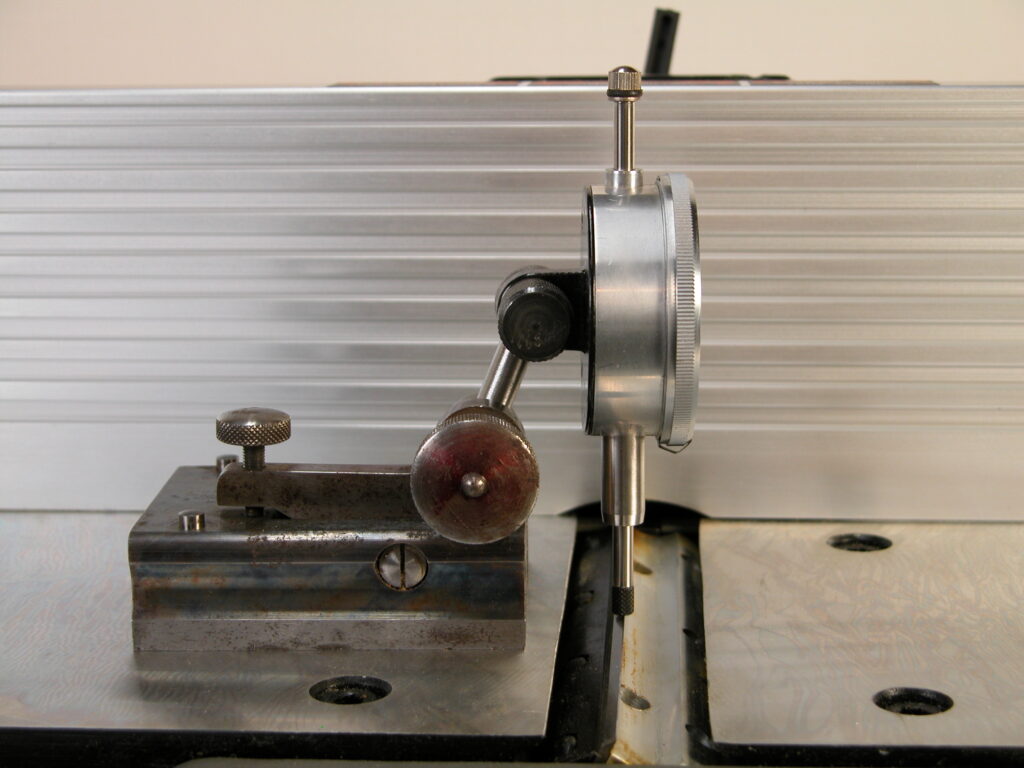

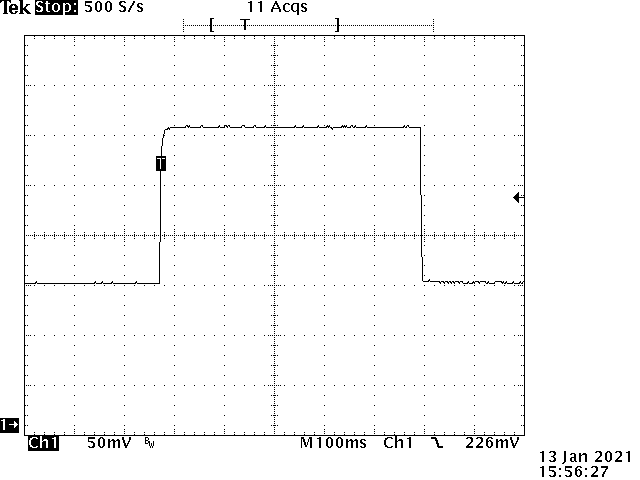

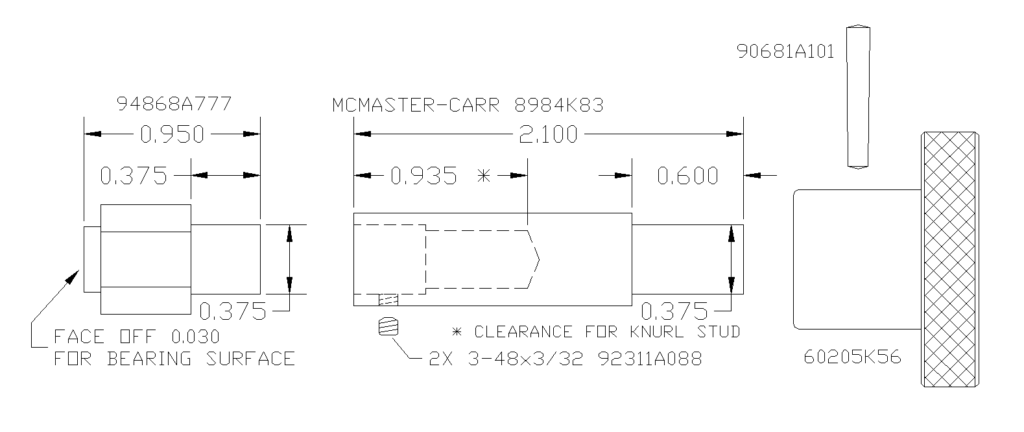

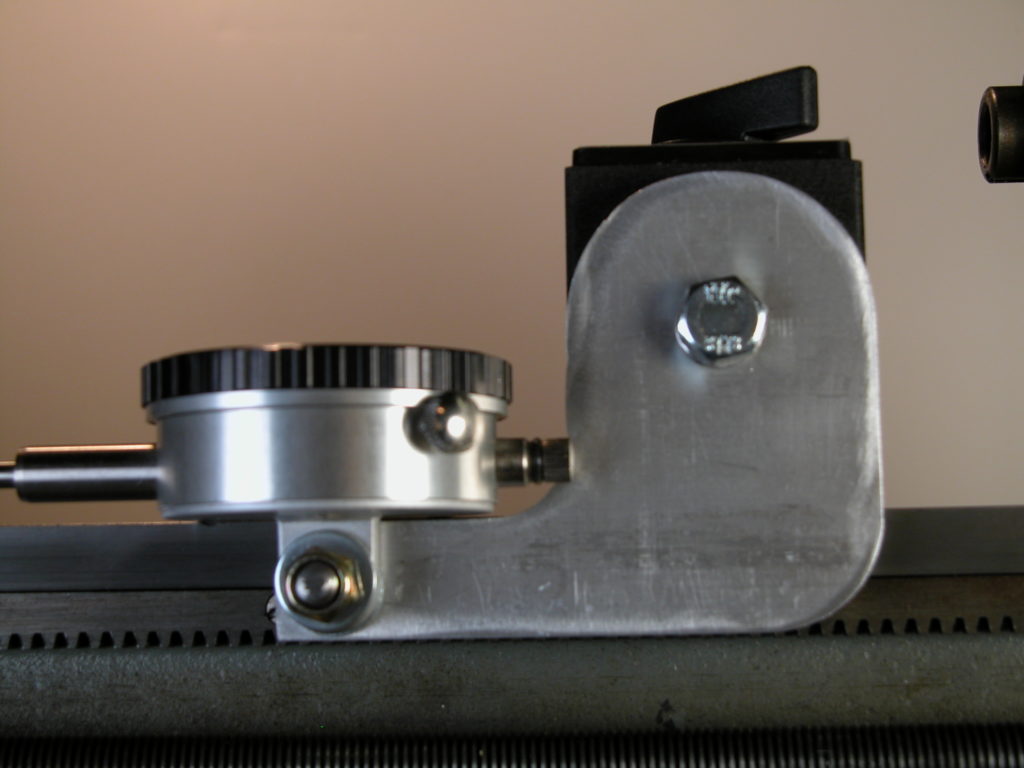

If you assume a pressure vessel, so the internal parts of the lander can be maintained at low or zero pressure to eliminate corrosion issues, the remaining problem is temperature. While 872°F exceeds the working temperature of most engineering technology, this environment is actually within the reach of the amateur. A typical self-cleaning kitchen oven runs at 900°F for a 4+ hour cycle. Not as fancy as NASA’s Venus Surface Simulator but useful for testing magnets, bearings, insulators, and mechanisms. One proposed solution to the power source problem is a windmill. While the average wind speed on Venus is only 3 MPH, the air density is 93 times higher than on Earth, providing plenty of power for a windmill. The main problems are bearings and power transfer. There are hybrid ceramic and carbon sleeve bearings which are rated for these temperatures although not these pressures in this atmosphere. Magnetic bearings eliminate friction and corrosion issues. Unfortunately, the current top magnet material, Neodymium-Iron-Boron, loses its magnetism at such temperatures. The next best, Samarium-Cobalt, has some high temperature versions that will only lose part of their strength. These can be preconditioned at temperature and then used. The older ALNICO 9 is able to work at Venus temperatures but starts out with about 1/3 the strength of Samarium-Cobalt. It’s not clear which of an ALNICO or SmCo solution would be lighter and/or smaller. Power could be transferred into the pressure vessel through a magnetic coupler consisting of a permanent magnet rotor surrounding an internal stator/generator separated by a nonmagnetic stainless steel cup in the wall of the pressure vessel. The overall idea is to figure out how to accomplish the science goals with technology that can operate at 872°F.

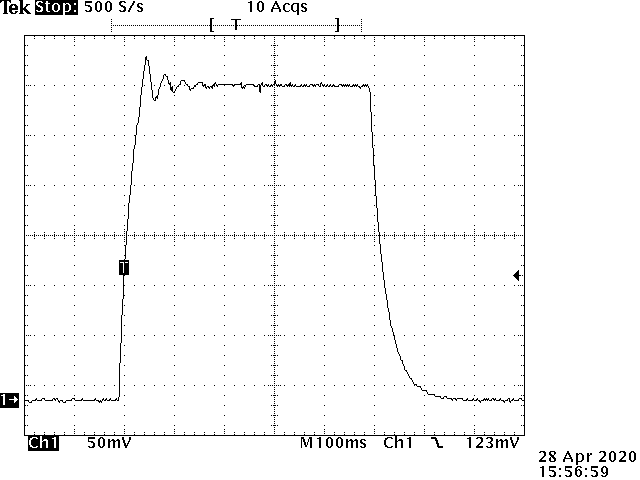

While NASA is looking into silicon carbide semiconductors, there are other possibilities. One possibility is old tech: vacuum tubes. In 1959 RCA invented the nuvistor, an advanced 0.4”x0.8” subminiature metal/ceramic vacuum tube. While the kinds of glass subminiature tubes used in the AN/PRC-6 “walkie-talkie” radio might work at these temperatures, the nuvistor technology would be a better starting point. One interesting feature was the RCA “dark cathode” that operated 630 degrees cooler than standard filaments. The reduced heater operating temperature resulted in greatly increased tube life and reliability. Starting at Venus temperatures would significantly reduce filament power. More advanced materials might allow a Venus ambient temperature cathode without heater power. The main problem is thermionic emission leakage from the grid, which limited the maximum temperature for the nuvistor. In an advanced design, vacuum depositing a silicon dioxide film on the grid might produce an analog of an insulated gate, suppressing grid leakage. There are metal-ceramic transmitter tubes like the 4CX150 that could be used as a starting point for developing high-temperature transmitter finals. Circuit connections would need to be welded rather than soldered. Most components would need to be rethought since traditional insulators will not work. Capacitors could be air, glass, mica, or suitable ceramics. Resistors could be metal film on ceramic or wire-wound on ceramic cores. Inductors would be printed on ceramic laminated substrates or air-wound on ceramic spacers. This is mostly existing radio technology.

One application would be small instrument packages that could be dropped in large numbers, consisting of a few simple sensors, a vacuum tube transmitter, and a solid electrolyte battery. These are batteries already in use by the military. They are extremely rugged and are completely solid and inactive at room temperature. They are intended to run at temperatures in the Venus range where the electrolyte melts and becomes active. Normally these batteries are actuated by pyrotechnic charges in artillery shells, rockets, or such but they could be part of a constellation of small Venus probes reporting temperature, seismic activity, or other data over wide areas for a limited time. They would easily survive a multi-year space flight prior to insertion. Multiple waves of probes could be used for longer data sets.

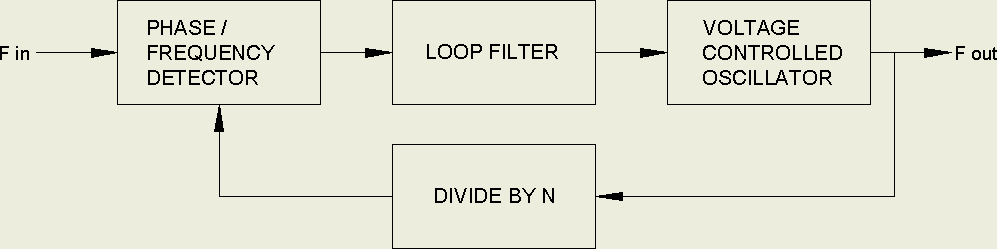

A long-term lander with a wind power source could support a wider range of sensors over a longer time frame. With a method to generate high enough voltages and development of a high temperature photo cathode, it should be possible to use an image or line orthicon to transmit spectra. Sapphire, ALON, or quartz windows would allow light sensing and slow-scan imaging. Decades of television before the 1960’s demonstrated that this is well within the range of tube technology. Mechanical scanning from an even earlier era is another possibility. With magnetic bearings in a vacuum environment the scanner power consumption could be very low. An idea brought up by various people is that you don’t need a computer or controller on the surface; you just need a receiver and transmitter in the lander with a control computer in the orbiter or orbiters. Kind of like a really expensive drone.

Although NASA is looking into making processor chips out of silicon carbide, a non-trivial task, for over a decade computers were designed with vacuum tubes. All logic functions, nand, nor, register, etc, can be handled by tubes, which in modern guise could be very small and very low powered compared to the best of the tube era, the nuvistor. While the original tube computers were monsters, they needed to run fast to solve major problems in a reasonable amount of time. You don’t need much of a computer to miss a rock or transmit some data. Specifically, a one-bit architecture like the PDP-8/S, WANG 500, or Motorola MC14500B with a little memory can compute anything with a minimum of physical hardware. While it would be slow, it would minimize size and power consumption while providing adequate control for the lander. A high temperature version of the Mercury computer program store could be a possibility here.

Please leave comments using the post in my comments category.