The jointer is the fundamental woodworking power tool for creating flat, square lumber without cup, bow, or twist. It is the first step in preparing wood for woodworking. The most critical jointer adjustment is ensuring that the cutter knives are precisely coplanar with the outfeed table. Otherwise you will not be able to successfully produce lumber that is flat and free of scarfs. The typical user guide instructions are to place a straightedge on the outfeed table overhanging the knives and then adjust the knives and/or the outfeed table until the knife edge just touches the straightedge across the width of the table, which is fairly imprecise and gets more difficult as your eyes age. The illustrated jig allows you to easily adjust the alignment to within 0.001″ or so.

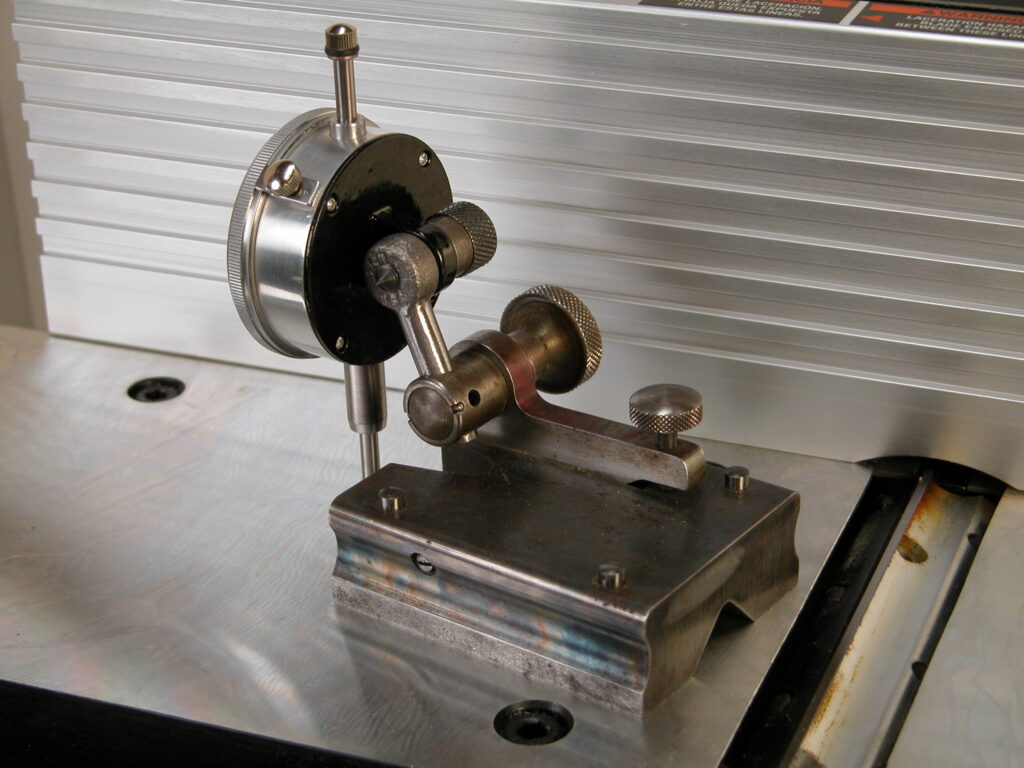

This one consists of an inexpensive ($15 at Amazon) dial indicator mounted on an old surface gauge base. Note the flat tip on the indicator plunger. Dial indicator plungers come with ball ends which are not suitable for measuring a knife edge. These ends are replaceable and all use 4-48 threads. The flat one above is www.mcmaster.com part number 20625A661. The mounting strut is a rod end blank, 6065K171. You can save yourself some machining by cutting down a 6066K34. It is important to get the axis of the plunger square to the surface. This makes the measurement insensitive to small changes in position.

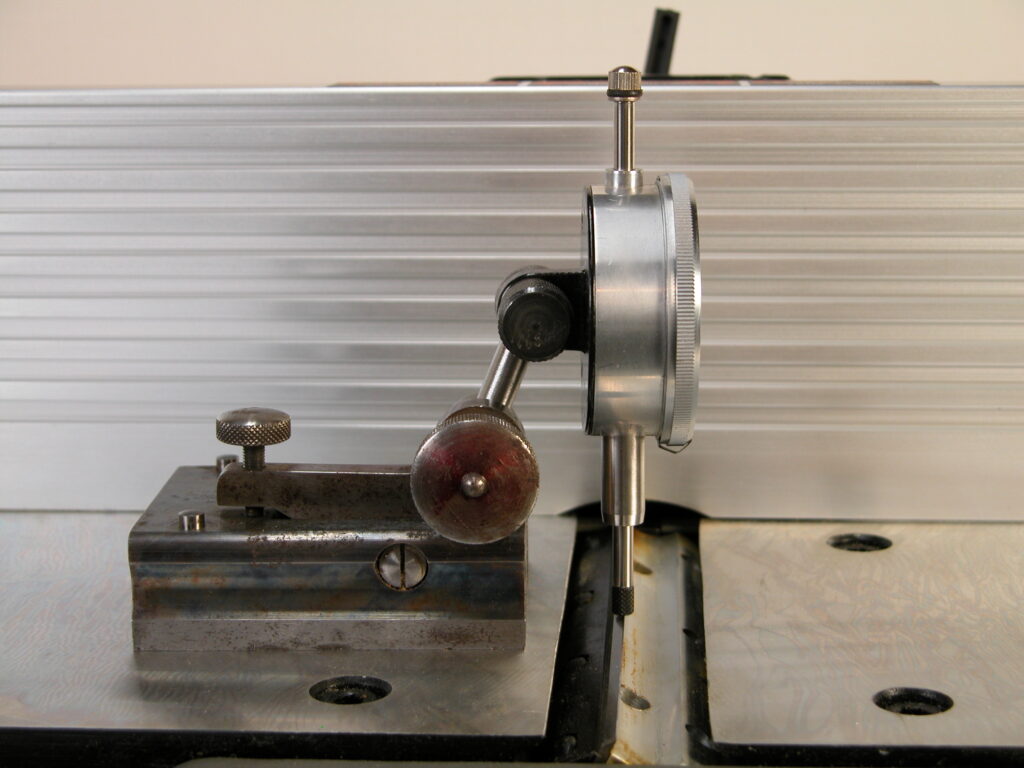

With the end of the plunger on the same surface as the base, turn the dial bezel until the indicator index (the small black triangle at the bottom of the dial in the top image) matches the dial reading. The plunger tip is hardened…if you drop it on your cutter edge you may damage the cutter. Pull up on the top of the plunger and slide plunger over the knife edge. Then gently lower the plunger.

Follow your jointer cutter/outfeed adjustment instructions to bring the dial reading into alignment with the index flag. Repeat across the outfeed table.

The base doesn’t need to be this fancy, just stable. I happened to have this on hand. A piece of angle iron with three screw adjustable support points to square it up would do as well.

Please leave any comments using the post in my comments category.